Templet Deutschland GmbH

> Components

> Strip guiding systems

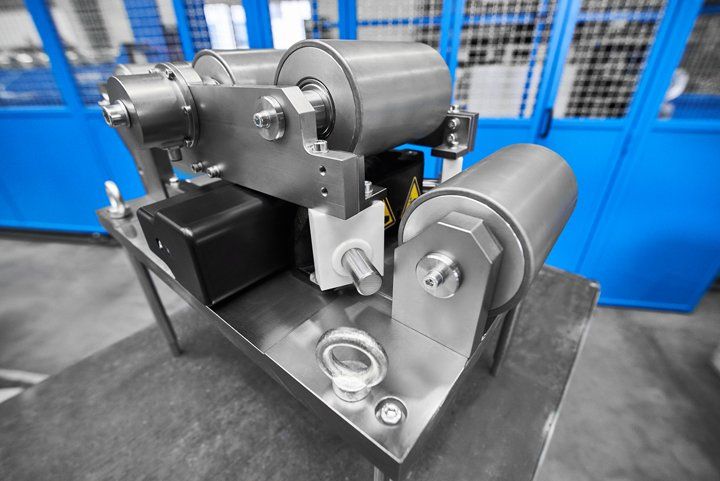

Strip guiding systems

Description

To ensure precise molding, we place guiding controls in front of the forming tools. A sensor observes where the strip is at all times and controls it precisely to the center of the formation via two movable rollers. As a result, the aluminum strip is always held in an ideal position for the welding process without the intervention of an operator. With this unique technology, there is no need to use the usual lateral guide rollers. Damage to the belt edges is a thing of the past. An Ethernet connection enables the customer to display the belt position on an external workstation at any time.

We would be happy to retrofit your existing system with a strip guiding system.

Advantages:

Advantages:

- Easy to use

- Can be used independently

- Industry 4.0

- Precise regulation

- no damage to the belt edges

Technical specifications:

- Max. Band width: 200mm

- Max. Band thickness: 2.5 mm

- Dimensions: depending on the version